Top Benefits of Buying Materials from a Sand and Gravel Screen Supplier

In the construction industry, precision and efficiency are everything. Whether you're a contractor, site manager, or project planner, the quality of your materials and equipment directly affects your bottom line. One often-overlooked component that plays a critical role in aggregate processing is the sand and gravel screen. These screens are essential for separating materials by size, ensuring consistency and quality in your final product.

Choosing a reliable sand and gravel screen supplier, can make all the difference. A trusted supplier offers not only high-quality screens but also expert guidance on selecting the right mesh size, material construction, and screen type for your specific needs. This ensures your operations run smoothly, with minimal downtime and maximum productivity.

Screen Size and Mesh Options for Every Application

One of the most significant advantages of working with a reputable supplier is access to a wide range of screen sizes and mesh options. The sand and gravel screen must be tailored to the type of material you're processing, whether it's coarse gravel, fine sand, or specialty aggregates.

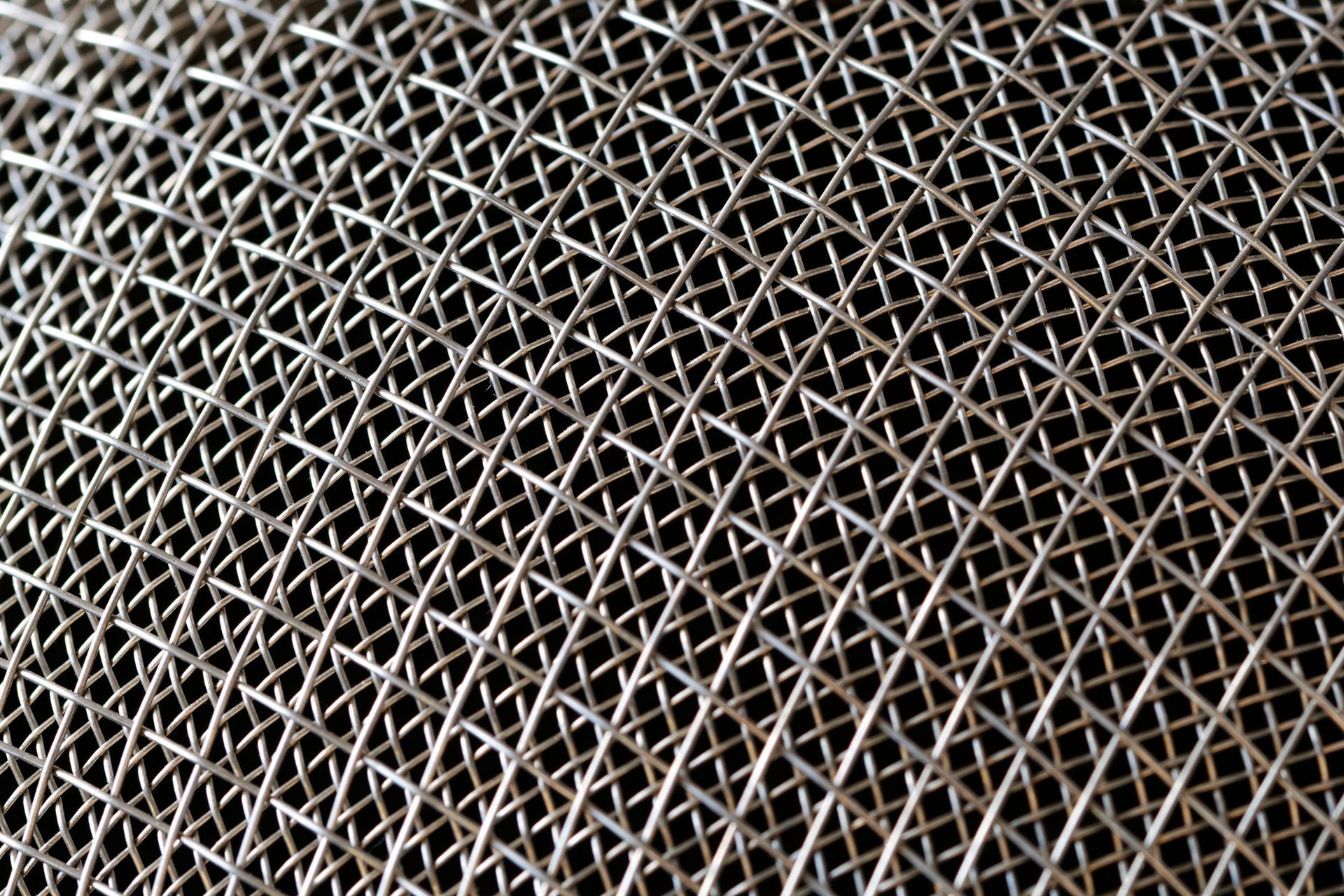

Trusted suppliers offer screens in various configurations, including square, slotted, and elongated meshes. These options allow you to fine-tune your screening process, improving accuracy and reducing waste. For example, a tighter mesh is ideal for fine sand, while a larger opening works better for gravel. The ability to customize your sand and gravel screen ensures optimal performance across different stages of your project.

Durability and Material Construction

Durability is non-negotiable when it comes to screening equipment. Construction sites are tough environments, and your sand and gravel screen needs to withstand constant wear and tear. Trusted suppliers use high-grade materials like stainless steel, high-tensile steel, and polyurethane to ensure long-lasting performance.

These materials resist corrosion, abrasion, and impact, reducing the need for frequent replacements. Additionally, screens from a reputable sand and gravel screen supplier in Eau Claire, WI, are often engineered with reinforced edges and welded seams, enhancing their structural integrity. This means fewer breakdowns, lower maintenance costs, and more uptime for your crew.

Efficiency and Capacity

Efficiency is the cornerstone of any successful construction project. A high-quality sand and gravel screen improves throughput, allowing you to process more material in less time. This not only speeds up project timelines but also reduces labor costs and equipment wear.

Trusted suppliers provide screens designed for high-capacity operations, with optimized open area ratios and vibration compatibility. These features ensure that your screening equipment can handle large volumes without clogging or slowing down. By investing in a screen that matches your operational needs, you enhance productivity and maintain consistent output quality.

Expert Support and Custom Solutions in Eau Claire, WI

Another key benefit of buying from a trusted supplier is access to expert support. Whether you're setting up a new site or upgrading existing equipment, choosing the right sand and gravel screen can be complex. Reputable suppliers offer consultation services to help you select the best screen type, mesh size, and material for your specific application.

They also provide custom fabrication options, allowing you to tailor screens to unique project requirements. This level of support ensures that your equipment integrates seamlessly with your workflow, minimizing disruptions and maximizing efficiency. A reliable sand and gravel screen supplier in Eau Claire, WI, will work with you to deliver solutions that fit your budget and timeline.

Maintenance Made Easy

Maintenance is a critical factor in equipment longevity and performance. High-quality Sand And Gravel Screen products are designed with maintenance in mind. Features like modular panels, quick-release fasteners, and self-cleaning meshes simplify upkeep, reducing downtime and labor costs.

Trusted suppliers often provide maintenance guides, replacement parts, and even on-site support to keep your screens in top condition. This proactive approach helps prevent costly breakdowns and ensures your screening equipment continues to perform at its best throughout the project lifecycle.

Proven Performance and Industry Reputation

When you buy from a trusted supplier, you're not just purchasing a product, you're investing in proven performance. Established suppliers have a track record of delivering reliable sand and gravel screen solutions to contractors, site managers, and project planners across the country.

Their reputation is built on quality, consistency, and customer satisfaction. By choosing a supplier with industry credibility, you gain peace of mind knowing that your equipment will meet or exceed expectations. This reliability translates into smoother operations, better project outcomes, and stronger client relationships.

Compliance and Safety Standards

Safety and compliance are paramount in the construction industry. A trusted supplier ensures that every sand and gravel screen meets relevant industry standards and regulations. This includes OSHA guidelines, environmental compliance, and material safety certifications.

Using compliant equipment not only protects your crew but also shields your business from legal and financial risks. Reputable suppliers stay up-to-date with evolving standards, providing products that align with best practices and regulatory requirements.

Long-Term Value and ROI

While upfront costs are important, long-term value is where trusted suppliers truly shine. A high-quality sand and gravel screen offers superior performance, reduced maintenance, and an extended lifespan of which contribute to a better return on investment. By minimizing downtime and maximizing efficiency, these screens help your complete projects faster and more cost-effectively. Over time, the savings in labor, materials, and equipment repairs far outweigh the initial purchase price. Investing in quality today means fewer headaches tomorrow.

Your choice of sand and gravel screen directly influences the efficiency, safety, and overall success of your construction projects. Partnering with a trusted supplier like Industrial Screen Supply, Inc. helps you access high-quality, durable, and efficient sand and gravel screens tailored to your project needs.

Ready to upgrade your screening equipment with reliable products and expert support?

Contact Industrial Screen Supply, Inc. today

to speak with one of our knowledgeable representatives. Let’s help you bring greater productivity and efficiency to your construction site.